Exploring biobased materials with Ralston Bau & Bioregion Vestland

Birgitta Ralston & Alexandre Bau are behind the design practice Ralston Bau, working with material science, research and design with an activistic approach.

With the ambitious Bioregion Vestland project, initiated by Design Region Bergen, they are exploring how experimental material design can help revitalize local industry on the Norwegian west coast.

We have spoken with Birgitta on the project and the way forward for new plastics.

# What is the Bioregion Vestland project about?

Bioergion Vestland is a year-long project about mapping organic waste in industrial quantities and envisioning new uses for these materials.

The goal is to shape a west-Norwegian production value-chain, delivering products and services that can replace fossil-fuel based plastic products. Today, the project includes 22 collaborating companies and institutions.

In addition to Ralston Bau, the design team includes Rå graphic design studio, Kaleidoscope architects, Siv Støldal fashion designer and Susanne Håvardstun, design thinker from PwC.

# We humans love plastic materials dearly. Will bioplastics ever be able to compete technically with conventional plastics - or must we redesign our products from scratch to come to terms with lower material performance?

If we use petrol-based plastics as much as we do today, it is more out of practicality and economy than love. It is an extremely cheap and durable resource, solving a multitude of needs.

For these reasons it is overused, ignoring it’s life cycle impact and the fact that plastics are seldom recyclable and never compostable. Fossil-based plastics are currently saturating our ecosystems, while we still produce them intensively.

Biopolymers can have similar mechanical properties to oil based ones, without compromising performance, while in the same time having the advantage of being compostable, and able to go back to natural eco-systems after ended life-cycle.

Making the switch does demand research, testing and specific adaptations for each industry and product, as with any other innovation; solutions are already out there. Beyond the question of using biomaterials, it is true that we should design more carefully; essential products that can be repaired, transformed recycled and composted.

# A lot of clever alternatives to plastic has been proposed the last years, but the use of petroleum based plastic seems to be very stable. Why is it so difficult to change course?

To change for bio-based resources, we need to reconsider current industrial value-chains and production methods. Because of the systems in place and the low cost of the fossil-based plastics, the cheapest is to keep going like usual. The same kind of investment that was operated from the pre-plastics society to a throwable plastic-culture, has to be put unconditionally into transforming to bio-based material industry.

“The difficulty lies, not in the new ideas, but in escaping from the old ones.”, said John Maynard Keynes (1883-1946)

# Local production of bio-based plastics is an awesome idea, requiring considerable investments. Do you see the will to make this happen in Norway?

Yes, here on the Norwegian west-coast, we witness a desire to explore the potential of regional value-chains and valorisation of organic waste through biomaterials.

Some businesses are working for maintaining the status-quo, by rather recycling, than phasing out plastics. Recycling is great, but there will always be many kinds of plastics that cannot be recycled, are poisonous to burn, or get lost into our water streams and natural systems.

So recycling plastics is not good enough, a paradigm-shift is needed. As part of this comes the handling of different and complex material streams. Not all the so called biomaterials are entirely fossil-free and biodegradable materials are not necessarily compostable. They are hybrid materials and can neither be recycled together with plastics or enter the organic waste stream.

# You have been researching algae as a component in bio-plastics. If we managed to develop industrial scale production of algae, how can we avoid the severe ecological problems that we see in the farmed salmon industry?

By carefully listening to sciences and being responsible, we have the possibility to create new bio- based industries. Macro-algae are like underwater forests and might be managed likewise, with unconditional respect for the eco-systems.

# What is your favourite historical petroleum plastic product - and how would you like to see it transformed?

We do not have a favourite plastic product, but if we look closely, several things we own and use, however natural they look, do have some part of fossil-fuel component, like waterproof clothes or single-use wipes.

Nature can provide other answers to the needs that these products meet. Nature is adapting, mutating, always seeking and reaching resilience in its ecosystems. The Biomimicry Institute is sharing concrete models and nature-like solutions to our issues, by asking the question: “What would Nature do?”.

The only way forward is to share knowledge across fields of competence, create regional circular value-chains including industrial organic waste-streams, then design, prototype, test and implement a post-fossil modern production.

GYI (Grow it yourself) planter from Ecovative

# What is your favourite bio-plastic product proposal and do you see it going into production anyday soon?

A lot of biomaterial alternatives are already certified and in production, available for applications in sectors such as product, furniture, health, food and construction. We love bio-materials that can replace generic and abundantly used fossil-based plastic products, like bubble-plastic packaging, with compostable plant-based material (Real Dirt Bag) and growing polystyrene-like alternative with Mycelium (Ecovative).

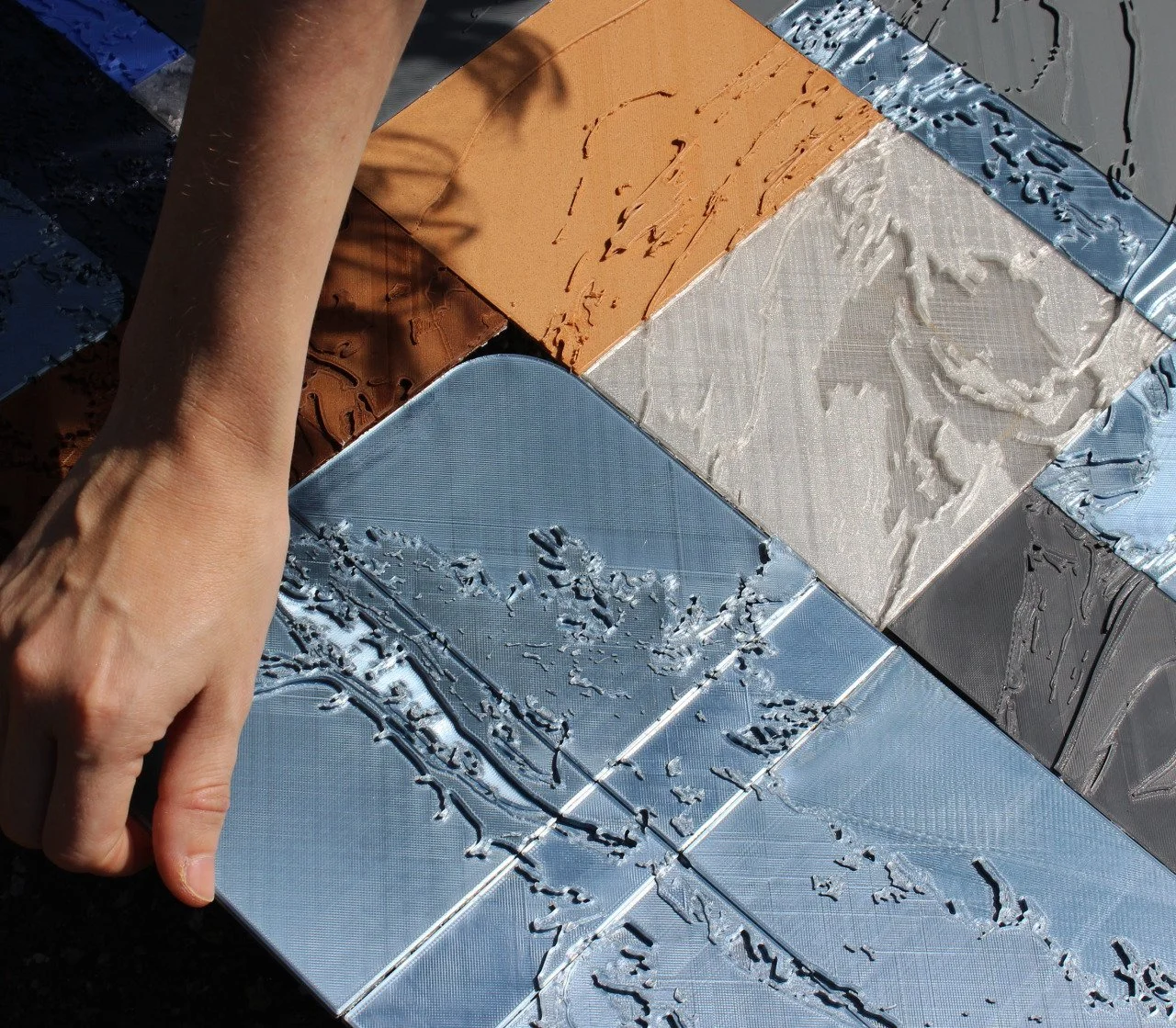

Also there are biomaterials that use natural fibres to produce self binding materials with agricultural fibre sources (Zelfo). There is a global awakening, with communities and industries investigating and qualifying regional, bio sourced materials, with a new range of colours, materials and surfaces.

Our favourite products are those that can go back into the natural eco-system after a long life. Nature does not know the concept of waste, it is circular by essence.

Ralston Bau is an idealist design studio decoding the complex world we move in. Their practice turns ideas into regenerative action, connect people to our common spaces and turn complex questions into essential objects.

Founders Birgitta Ralston and Alexandre Bau are inspired by human rituals and contexts to shape scenarios that come alive in narrative spaces and objects.

The Bioregion Vestland project is initiated by Design Region Bergen and funded in part by Hordaland County Municipality.

ralstonbau.com

idealist.institute

bioregionvestland.com

More on plastic:

More conversations: